Thanks again. I'll keep that in mind and add that gear/timing set to the list.

I'll have the questions in red just to make things a little easier.

But I uncovered the engine and drug it out today. I removed the last thing in it, the cam. Well there are a few small things in it, such as the lifters (

lifters don't need replacing right? they slide smoothly), a main bearing, and the cam bearings (i dont think i'll have those replaced). Besides that, there is just the bare block, and lots of crusty coolant.

The block...

Any predictions if the block will need to be bored more or not because of the rust? I'm thinking it will but i'm not sure, it would be nice if a good honing could get rid of this rust. It is surface rust that you can remove most of with a wool pad.

Tops of cylinders are fine, the heat moisture from the dryer settled on the bottom.

The cylinder bore. 8.008

I slid a lifter out, looks fine to me.

The cam that i just pulled

The crank. There is alittle bit of rust. I emagine the machine shop will take care of it nicely.

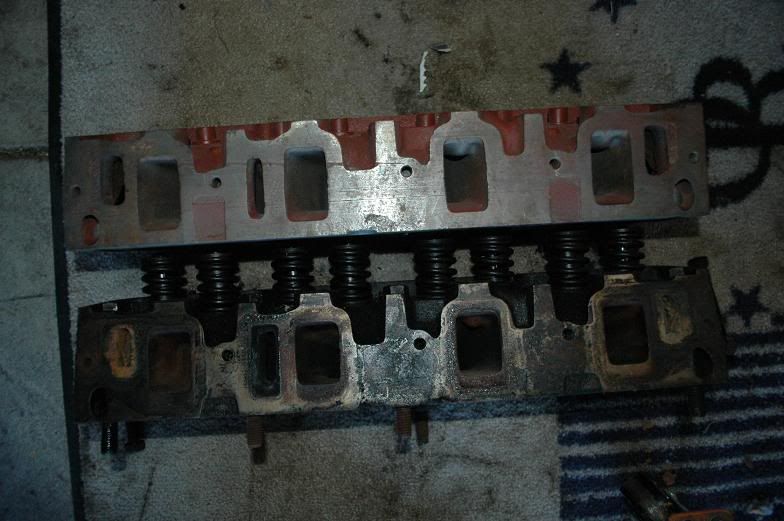

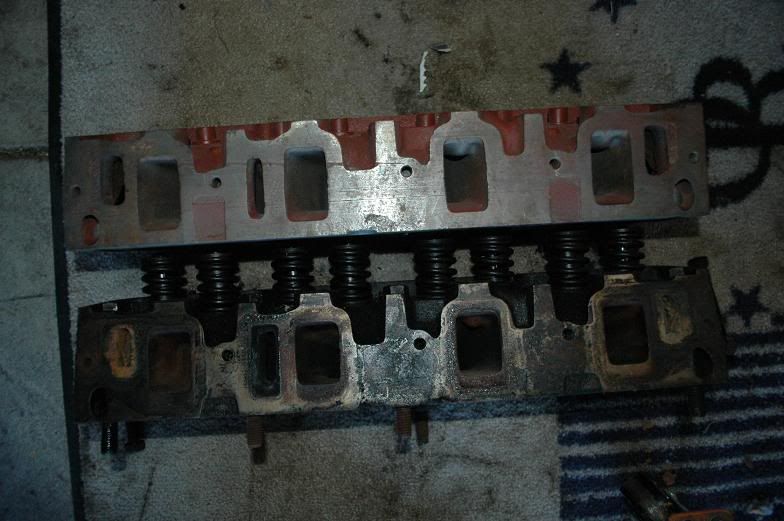

And here are my EDC heads compared to the stock heads.

Should i swap things over to the EDC heads and run them, or run the stock heads? I asked this before but now there are comparison pictures..

THe one big difference i see, are the much bigger ports (intake side)

The mic is adjusted to the EDC head port, to show how much bigger they are compared to my stock heads.