Rough head exhaust surfaces, gaskets, and avoiding leaks.

Moderators: Ranchero50, DuckRyder

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Hi Jamie and 70_F100, thanks for replying!

I see what you're getting at with the thread depth. Since I ordered some 1 and 1/8" long bolts, I'll use those--those should give me about 9/16" thread engagement (out of a possible 11/16" in the head). I'm afraid that if I used 1 and 1/4" bolts, they might bottom out in the threads before being torqued, since they might use the entire 11/16" of thread capacity.

As for what type of bolts to use, the ones I ordered were zinc plated grade 8's with regular sized heads. I understand the idea of using softer bolts (or even stainless bolts) to avoid having major trouble should they need to be drilled, but isn't it true that a grade 8 bolt is much less likely to need to be drilled? Because their heads are less likely to snap off?

Thanks for all the superb advice Folks!

Robroy

I see what you're getting at with the thread depth. Since I ordered some 1 and 1/8" long bolts, I'll use those--those should give me about 9/16" thread engagement (out of a possible 11/16" in the head). I'm afraid that if I used 1 and 1/4" bolts, they might bottom out in the threads before being torqued, since they might use the entire 11/16" of thread capacity.

As for what type of bolts to use, the ones I ordered were zinc plated grade 8's with regular sized heads. I understand the idea of using softer bolts (or even stainless bolts) to avoid having major trouble should they need to be drilled, but isn't it true that a grade 8 bolt is much less likely to need to be drilled? Because their heads are less likely to snap off?

Thanks for all the superb advice Folks!

Robroy

- BobbyFord

- 100% FORDified!

- Posts: 5383

- Joined: Sun Feb 04, 2007 9:52 am

- Location: Chatsworth, California

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

What does a set of head gaskets cost? Minimal. I'd pull the heads and have the exhaust side of the head milled. I'm surprised they didn't do it while they were building the motor. I have stock manifolds on my motor with milled surfaces on the heads and manifolds, no gaskets, no leaks.

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Hey BobbyFord, thanks for your advice!

I thought about doing this, but I don't really want to dig in to the motor. As you know I'd need to remove the intake manifold and all the rocker arm stuff. I just don't want to bother with that if it'll work as-is. Especially since I have these space-age gaskets on the way.

Maybe later on I'll regret not doing it while it's this easy!

Thanks BobbyFord!

Robroy

I thought about doing this, but I don't really want to dig in to the motor. As you know I'd need to remove the intake manifold and all the rocker arm stuff. I just don't want to bother with that if it'll work as-is. Especially since I have these space-age gaskets on the way.

Maybe later on I'll regret not doing it while it's this easy!

Thanks BobbyFord!

Robroy

- DuckRyder

- Moderator

- Posts: 4941

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

I'm with fitzwell on this one:

nitroseal, ultra copper...

Oh and it is dissapointing that thye didn't properly surface the exhaust face...

nitroseal, ultra copper...

Oh and it is dissapointing that thye didn't properly surface the exhaust face...

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- fomocoguy

- 100% FORDified!

- Posts: 1548

- Joined: Mon Nov 12, 2007 10:04 pm

- Location: St. Louis, MO

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

I'm just not so sure how that would work with the weld bead headers. They wouldn't sit flat against the exhaust flange at all...DuckRyder wrote:I'm with fitzwell on this one:

nitroseal, ultra copper...

Oh and it is dissapointing that thye didn't properly surface the exhaust face...

EDIT Sorry, nevermind. I didn't realize the "nitroseal" you speak of was a gasket. My bad!

Joe

1971 F100 flareside 8ft

1964 Chrysler New Yorker Town and Country wagon

2006 Dodge Ram 2500 cummins

2005 Ford Ranger

1971 F100 flareside 8ft

1964 Chrysler New Yorker Town and Country wagon

2006 Dodge Ram 2500 cummins

2005 Ford Ranger

- fomocoguy

- 100% FORDified!

- Posts: 1548

- Joined: Mon Nov 12, 2007 10:04 pm

- Location: St. Louis, MO

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Rest easy, robroy. Everybody has their own way of fixing this common problem with exhaust leaks, but I can assure you the reflex's work spectacularly. You will be happy with them.

Joe

1971 F100 flareside 8ft

1964 Chrysler New Yorker Town and Country wagon

2006 Dodge Ram 2500 cummins

2005 Ford Ranger

1971 F100 flareside 8ft

1964 Chrysler New Yorker Town and Country wagon

2006 Dodge Ram 2500 cummins

2005 Ford Ranger

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Hey Robert and FoMoCoGuy, thanks for replying!

I went ahead with the RemFlex gaskets (but thanks to Fitzwell and Robert for recommending another type--I'll switch to that if I have any problems with the RemFlex gaskets)!

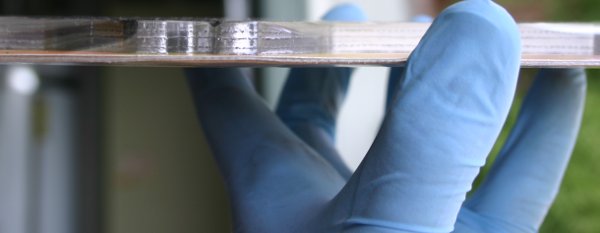

The RemFlex gaskets came with a sample of the graphite material they're made of. The sample is made to play around with, since they know you'll not be able to resist the urge to "squish" the gasket material a little bit!

Here's the package:

These gaskets are thick!

Installing on the passenger's side:

Installing on the driver's side:

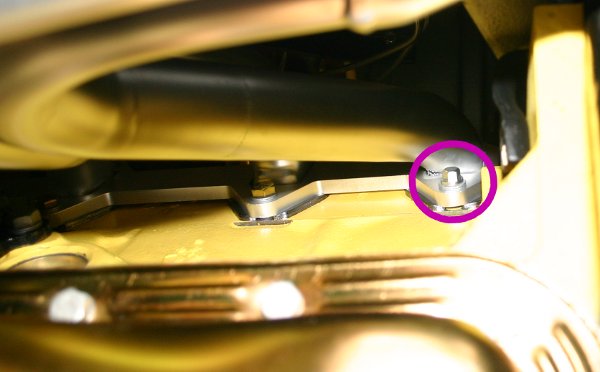

Here are the fasteners I used for 15 out of 16 holes. They're 1 and 1/8" long, zinc plated, grade 8 bolts with Nord-Locks and anti-seize.

Because of a tight contour on the driver's side header, on the bottom and in back, I used one of the 1" bolts supplied by Hedman on that one (the larger head of my 1 and 1/8" bolt made it impossible to use there).

The finished passenger's side:

The finished driver's side:

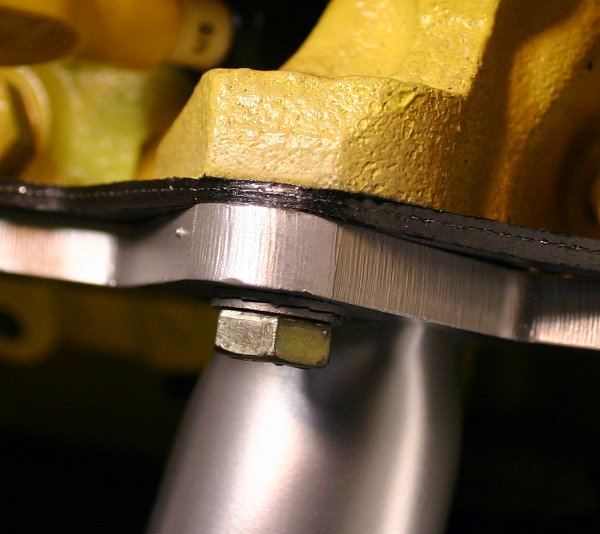

You can see how much the gasket material squished down. I torqued the bolts to about 18 ft/lbs--the RemFlex package said to use 15-20 ft/lbs, since the gasket material squashes so easily. I couldn't get to all of the bolts with my little torque wrench so I had to guess on some of them!

I think this case is closed for now!

Thank you all very much for helping me with this topic!

Robroy

I went ahead with the RemFlex gaskets (but thanks to Fitzwell and Robert for recommending another type--I'll switch to that if I have any problems with the RemFlex gaskets)!

The RemFlex gaskets came with a sample of the graphite material they're made of. The sample is made to play around with, since they know you'll not be able to resist the urge to "squish" the gasket material a little bit!

Here's the package:

These gaskets are thick!

Installing on the passenger's side:

Installing on the driver's side:

Here are the fasteners I used for 15 out of 16 holes. They're 1 and 1/8" long, zinc plated, grade 8 bolts with Nord-Locks and anti-seize.

Because of a tight contour on the driver's side header, on the bottom and in back, I used one of the 1" bolts supplied by Hedman on that one (the larger head of my 1 and 1/8" bolt made it impossible to use there).

The finished passenger's side:

The finished driver's side:

You can see how much the gasket material squished down. I torqued the bolts to about 18 ft/lbs--the RemFlex package said to use 15-20 ft/lbs, since the gasket material squashes so easily. I couldn't get to all of the bolts with my little torque wrench so I had to guess on some of them!

I think this case is closed for now!

Thank you all very much for helping me with this topic!

Robroy

Last edited by robroy on Sun Sep 06, 2009 9:40 am, edited 1 time in total.

- 71PA_Highboy

- Blue Oval Fanatic

- Posts: 923

- Joined: Tue May 23, 2006 11:32 am

- Location: Denver of the East

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Robroy,

If those ever start to loosen up (and my money is that they will) buy some 'Stage-8' header bolts.

JMHO,

Eric

If those ever start to loosen up (and my money is that they will) buy some 'Stage-8' header bolts.

JMHO,

Eric

Got Ford?

2 EarlyBroncos (68,69)

2 Classic Mustangs (69,70)

1 F250 4x4 (71) - OB - 360, NP435, D24, HPD60 4.10, D60,

1 94 Ranger, 2.3, 5spd

1 Lincoln Mark VIII

2 EarlyBroncos (68,69)

2 Classic Mustangs (69,70)

1 F250 4x4 (71) - OB - 360, NP435, D24, HPD60 4.10, D60,

1 94 Ranger, 2.3, 5spd

1 Lincoln Mark VIII

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Hey Eric, thanks for the advice! I'll keep an eye on the bolts to see if they loosen up or not, and will follow your advice if they do.

Thanks again,

Robroy

Thanks again,

Robroy

- DuckRyder

- Moderator

- Posts: 4941

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Looking good,

So when should we expect the first run video?

So when should we expect the first run video?

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Hey Robert thank you!

It won't be long now 'til the first run video! I've proven to myself time and time again since this project began what a bad judge I am of how long things will take. But I am certain that the first run video will be posted here before Halloween. That's probably not a very exciting estimate!

On the other hand, it could be as soon as two weeks from now. Maybe I'll shock myself and it won't even be that long!

Thanks Robert!

Robroy

It won't be long now 'til the first run video! I've proven to myself time and time again since this project began what a bad judge I am of how long things will take. But I am certain that the first run video will be posted here before Halloween. That's probably not a very exciting estimate!

On the other hand, it could be as soon as two weeks from now. Maybe I'll shock myself and it won't even be that long!

Thanks Robert!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Good morning!

So the RemFlex RF3050 gaskets seemed to perform flawlessly during the few minutes the engine actually ran! But as y'all know by now, I had to pull the headers off because of the saga documented in, What's this loud tapping sound from my new engine?

The gaskets came apart badly when I pulled them off. Here's a photo borrowed from the thread referenced above. Note that you can click on this image for a much larger version.

When I first ordered my gaskets on August 31st, 2009, I heard from the woman on the phone that the gaskets were covered under warranty even if I had to remove them for some reason and they came apart. Or at least that's what I thought I heard.

Today I called RemFlex to ask about this, and heard that they do not cover that type of situation under warranty. I guess I misunderstood when I ordered the gaskets! Oh well. The guy was nice enough to give me $20 off a replacement set, so the gasket set was $38.99 instead of the original $58.99.

I think that's more than fair, since I'm sure these gaskets are designed to be installed only once. I was just a little confused about the warranty policy I heard before ordering them versus the policy I heard when trying to exercise the warranty. I certainly could have mis-heard the woman the first time around, but I was pretty sure I heard her loud and clear!

Since the heads on the newly rebuilt engine (built by Tom Lucas) will be properly surfaced, I probably didn't really need these RemFlex gaskets at all. But I figured it couldn't hurt to use one of the best gaskets available, even on a near-perfect surface.

Thanks for reading and for the excellent advice!

Robroy

So the RemFlex RF3050 gaskets seemed to perform flawlessly during the few minutes the engine actually ran! But as y'all know by now, I had to pull the headers off because of the saga documented in, What's this loud tapping sound from my new engine?

The gaskets came apart badly when I pulled them off. Here's a photo borrowed from the thread referenced above. Note that you can click on this image for a much larger version.

When I first ordered my gaskets on August 31st, 2009, I heard from the woman on the phone that the gaskets were covered under warranty even if I had to remove them for some reason and they came apart. Or at least that's what I thought I heard.

Today I called RemFlex to ask about this, and heard that they do not cover that type of situation under warranty. I guess I misunderstood when I ordered the gaskets! Oh well. The guy was nice enough to give me $20 off a replacement set, so the gasket set was $38.99 instead of the original $58.99.

I think that's more than fair, since I'm sure these gaskets are designed to be installed only once. I was just a little confused about the warranty policy I heard before ordering them versus the policy I heard when trying to exercise the warranty. I certainly could have mis-heard the woman the first time around, but I was pretty sure I heard her loud and clear!

Since the heads on the newly rebuilt engine (built by Tom Lucas) will be properly surfaced, I probably didn't really need these RemFlex gaskets at all. But I figured it couldn't hurt to use one of the best gaskets available, even on a near-perfect surface.

Thanks for reading and for the excellent advice!

Robroy

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Good afternoon!

Now that the FE Specialties engine has been installed, it's time to put the headers on again. Since the heads received an expert porting job from Tom Lucas, this time I'm paying more attention to the exhaust gaskets (to make sure they don't restrict the exhaust flow, effectively undoing some of Tom's great work).

I tried to light up the area to improve the quality of my photos, but nothing beats natural lighting.

Here are the fresh exhaust ports--what a big improvement! Tom's machinist did a great job here. The only cylinder that remained slightly eroded was #8, and it's still a major improvement over its previous condition!

You can click on any of these images to see dramatically larger, higher definition editions. The focus isn't perfect on the entire mating surface in every photo; my depth of field was too narrow. But you can the idea!

Here's the replacement gaskets from RemFlex.

They came with another sample! If anybody would like this sample to play with, PM me and I'll mail it to you.

And here's the RF3050 out of its box.

Here's the gasket that came with the Hedman 89810 headers, laying directly over the RemFlex RF3050. Can you see that the RemFlex gasket is actually a little shorter (along the bottom lip)? Note that the Hedman gaskets are a very close fit to the ports on the 89810 headers, and also a very close fit to the ports on my heads.

And here's a close-up that shows off the size difference.

Because the Hedman gaskets fit both the headers and the exhaust ports on my heads very closely, you can see that if I were to install the RemFlex RF3050 gaskets in their current shape, they'd partially block the exhaust ports.

I can think of a few options for addressing this:

Thanks very much for the superb guidance!

Robroy

Now that the FE Specialties engine has been installed, it's time to put the headers on again. Since the heads received an expert porting job from Tom Lucas, this time I'm paying more attention to the exhaust gaskets (to make sure they don't restrict the exhaust flow, effectively undoing some of Tom's great work).

I tried to light up the area to improve the quality of my photos, but nothing beats natural lighting.

Here are the fresh exhaust ports--what a big improvement! Tom's machinist did a great job here. The only cylinder that remained slightly eroded was #8, and it's still a major improvement over its previous condition!

You can click on any of these images to see dramatically larger, higher definition editions. The focus isn't perfect on the entire mating surface in every photo; my depth of field was too narrow. But you can the idea!

Here's the replacement gaskets from RemFlex.

They came with another sample! If anybody would like this sample to play with, PM me and I'll mail it to you.

And here's the RF3050 out of its box.

Here's the gasket that came with the Hedman 89810 headers, laying directly over the RemFlex RF3050. Can you see that the RemFlex gasket is actually a little shorter (along the bottom lip)? Note that the Hedman gaskets are a very close fit to the ports on the 89810 headers, and also a very close fit to the ports on my heads.

And here's a close-up that shows off the size difference.

Because the Hedman gaskets fit both the headers and the exhaust ports on my heads very closely, you can see that if I were to install the RemFlex RF3050 gaskets in their current shape, they'd partially block the exhaust ports.

I can think of a few options for addressing this:

- I could trim the RemFlex gaskets to be as tall as the Hedman gaskets, then use the RemFlex gaskets.

- I could use the Hedman gaskets. Since my head surfaces are in pretty good shape now that might be OK.

- I could install these RemFlex gaskets as-is and not worry about it. I'd just hate to undo Tom's awesome porting work!

- I could order some entirely different exhaust gaskets.

Thanks very much for the superb guidance!

Robroy

- DuckRyder

- Moderator

- Posts: 4941

- Joined: Mon Jul 19, 2004 3:04 pm

- Location: Scruffy City

- Contact:

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

The truck heads are "low exit".

I think the biggest problem is that the extra holes are going to decrease the seal area and the top of the port in the remflex may be so high the sealing bead on the header will have trouble sealing. These issues are evident on the old remflex gasket. I would ask them if they have a "truck" gasket and if not use the headman gaskets...

I think the biggest problem is that the extra holes are going to decrease the seal area and the top of the port in the remflex may be so high the sealing bead on the header will have trouble sealing. These issues are evident on the old remflex gasket. I would ask them if they have a "truck" gasket and if not use the headman gaskets...

Robert

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

1972 F100 Ranger XLT (445/C6/9” 3.50 Truetrac)

"An unarmed man can only flee from evil, and evil is not overcome by fleeing from it." -- Jeff Cooper

- robroy

- 100% FORDified!

- Posts: 3768

- Joined: Sun Jul 06, 2008 4:36 pm

- Location: California, Salinas

Re: Rough head exhaust surfaces, gaskets, and avoiding leaks.

Good afternoon Robert, thanks for your excellent reply!

Now that my head surfaces are decent, if I were to go with the Hedman gaskets, wouldn't it be pretty easy to replace them later on if they turned out to leak? Isn't that a relatively minor job?

Robert, thanks very much for your fantastic and quick reply!

Robroy

Oh! Gosh, thanks for pointing that out. I hadn't been thinking about port size differences because I heard from RemFlex that their RF-3050 gasket was designed for the 89810 headers! Perhaps that was not the case after all.DuckRyder wrote:The truck heads are "low exit".

Now that you mention it, I see just what you mean.DuckRyder wrote:I think the biggest problem is that the extra holes are going to decrease the seal area

Perhaps oddly, the top side looks about the same on both the RemFlex and Hedman gaskets--only the bottom side has the pronounced difference.DuckRyder wrote:and the top of the port in the remflex may be so high the sealing bead on the header will have trouble sealing.

And so they are! So much time has passed now that I don't remember why I didn't pay more attention to these issues at the time. Oh well!DuckRyder wrote:These issues are evident on the old remflex gasket.

I could call them, if I can stand to wait until Monday!DuckRyder wrote:I would ask them if they have a "truck" gasket and if not use the headman gaskets...

Now that my head surfaces are decent, if I were to go with the Hedman gaskets, wouldn't it be pretty easy to replace them later on if they turned out to leak? Isn't that a relatively minor job?

Robert, thanks very much for your fantastic and quick reply!

Robroy